Friction is the Enemy: Why Your Parts are Failing and How Superior Plating Fixes Them

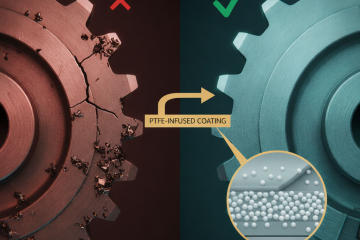

If you’re an OEM, you know the drill. You design a perfect component, it looks great on the CAD screen, but three months into field testing, it’s galling, seizing, or just wearing down into expensive dust. Usually, the culprit is simple: friction. Most people try to solve this with grease. But grease is messy, it attracts grit, and eventually, it fails. That’s where our high performance electroless nickel composites come in. They’re not just coatings; they basically give your metal parts a permanent, built-in “self-lubricating” skin. What’s Actually Happening in the Tank? We aren’t just painting stuff here. This is a chemical reaction. We take electroless nickel—which is already tough as nails and highly corrosion-resistant—and we co-deposit microscopic particles of PTFE (you probably know it as Teflon™) or Boron-Nitride throughout the entire layer. This isn’t some cosmetic treatment on the surface. Whether you select Pen-Tuf® (EN with PTFE) or BNEN Read more