Why Electroless Nickel Plating is Essential in Defense Manufacturing

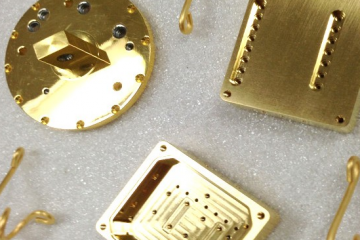

A Coating That Goes Beyond Protection The defense and aerospace industries require components made with high precision to tight tolerances. Every component must perform flawlessly, often under extreme conditions. That’s why electroless nickel plating is frequently the coating of choice for mission-critical parts. Often referred to as an “engineering coating,” electroless nickel offers both corrosion protection and precision to plus or minus 0.0001” of thickness. ___________________________________________________________________ Why Defense Engineers Choose Electroless Nickel 1. Uniform Thickness on Complex GeometriesUnlike electrolytic plating, which relies on electrical current, electroless nickel is deposited through a chemical process. This means quality plating can be applied to internal cavities, deep bores, and intricate geometries. Clearly, this meets the needs of critical components in weapons systems and flight hardware. 2. Hardness and Wear ResistanceFormulations that vary the amount of phosphorus in the electroless nickel deposit can increase hardness and improve corrosion resistance. Higher deposit hardness can improve Read more…