Metal Finishing in Aerospace

In aerospace manufacturing, metal finishing is rarely the first thing discussed. It usually comes up later, often after a problem is identified. Corrosion. Binding during assembly. Parts that pass inspection but don’t perform as expected.

When that happens, surface treatment gets a closer look.

Aerospace metal finishing isn’t just about looks. It’s about how parts behave over time. Temperature swings, vibration, moisture, lubricity, service intervals. These conditions expose weaknesses quickly. Finishing processes exist to manage these stresses, not to decorate the component.

Plating for aerospace parts is often selected for very specific reasons. Corrosion resistance. Controlled friction. Wear protection. In some cases, the finish matters just as much as the base material.

Standards Are Expected

Most aerospace finishing work is tied to specifications like SAE AMS, ASTM, or MIL-DTL. These define preparation, coating requirements, and inspection methods. Performing to these specs is mandatory. Everyone in the industry knows that.

What’s Harder is Doing it the Same Way Every Time

Repeatability is usually where problems show up. Small variations in prep, thickness, or handling don’t always cause immediate failures. They show up later, in service or during maintenance.

Common Processes, Different Outcomes

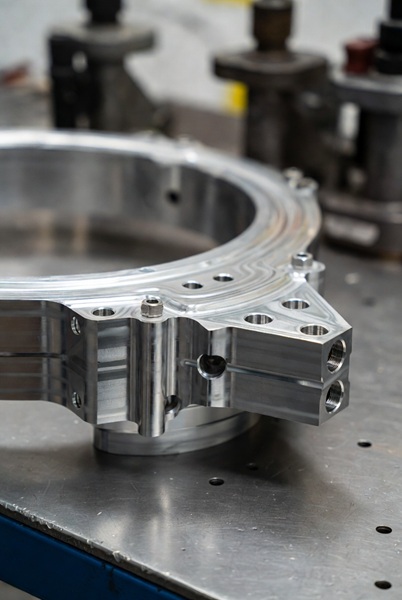

Electroplating is widely used, especially for fasteners and mechanical components. However, electroless plating is often the preferred method for tight tolerances and uniform coverage.

Passivation is often applied to stainless steel components. It sounds simple. In practice, it’s easy to underestimate how much surface prep matters.

None of these processes are interchangeable. Using the wrong one usually doesn’t fail immediately. It fails later.

Lightweight Materials Change the Rules

Aerospace designs continue to push toward lighter structures. Aluminum, magnesium and titanium alloys are standard in many applications. These require careful finishing to avoid long-term issues.

As materials evolve, finishing processes have had to adapt. The goal stays the same, protection and consistency, but the margin for error keeps shrinking.

Where Finishing Really Shows

Before going into service, finish quality reveals itself during inspections. Afterwards, operations and maintenance cycles expose how well the coatings protect the hardware. Defects affect service life, replacement schedules and, cost.

Choosing a Finishing Partner

Aerospace manufacturers don’t just need a shop that can coat parts. They need a partner who understands specifications, materials, and how finishes behave in real operating conditions.

At Advanced Surface Technologies, aerospace metal finishing is handled with that responsibility in mind. Controlled processes. Consistent results. Finishes designed to perform long after delivery.