The Science of Corrosion Resistance: How Electroless Nickel Protects Metal Components

Corrosion has this annoying habit of showing up when you’re not really paying attention. You think a part looks fine, and then a few months later you notice a bit of roughness or a tiny pit that definitely wasn’t there before. You’ve seen that happen on components that were supposed to “last forever,” and it’s frustrating. That’s one of the reasons high-phosphorous electroless nickel (EN) has become a “go-to” solution for designers working with close-tolerance metal parts for tough environments.

The Secret Behind Uniform Coverage

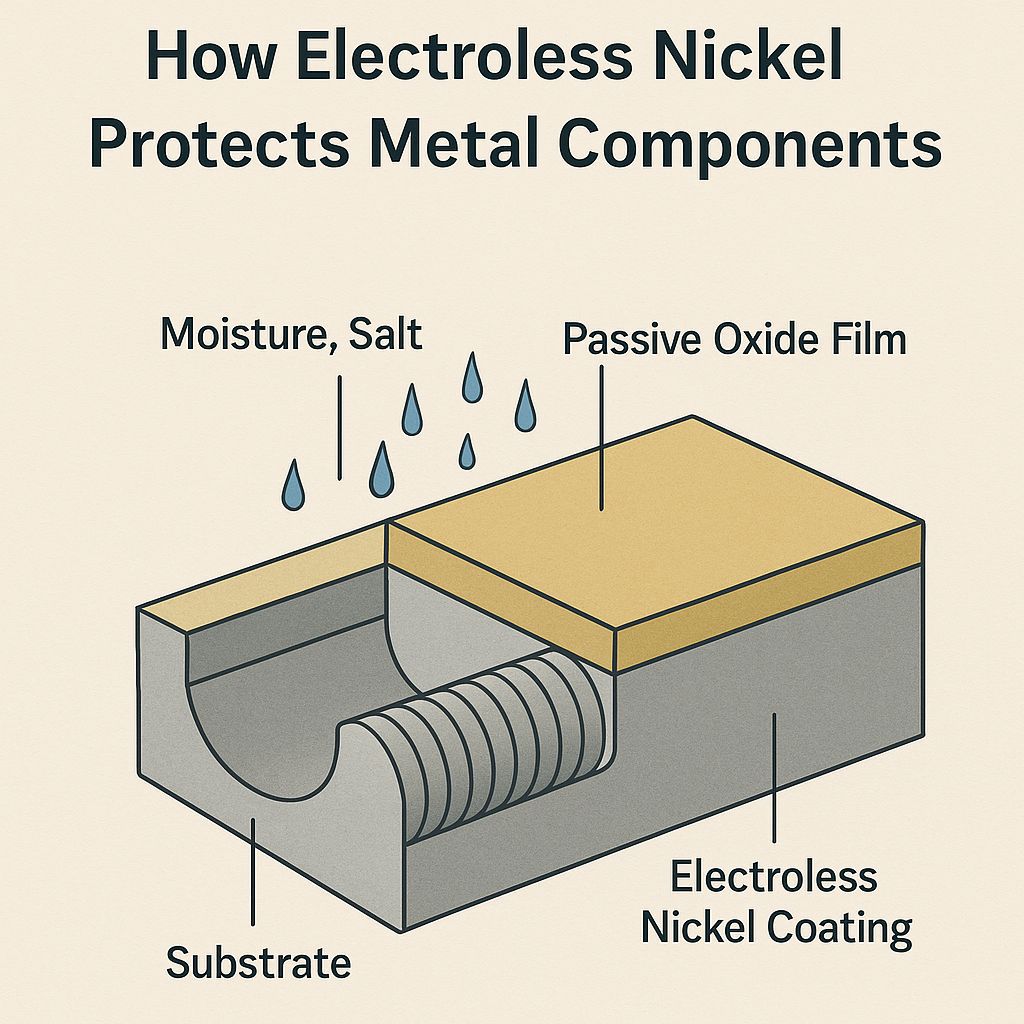

One valuable thing about EN is that it doesn’t rely on electricity so it has the ability to maintain a consistent deposit thickness without heavy build-up around edges and holes. The coating builds through a chemical reaction in the plating tank and, because of that, it covers everything evenly — even threads or deep recesses that can cause tolerancing trouble with electroplating. When the whole part gets coated the same way, there are fewer surprises later.

The nickel-phosphorus layer that forms is pretty tough on its own. High-phosphorus (10+%) EN creates a smooth, amorphous structure that resists corrosive attack. On top of that, the coating naturally forms a thin oxide film — nothing dramatic, but enough to slow down many things trying to eat through the coating.

Where EN Works Best

EN gets used on all kinds of machined and cast parts. Specifiers call-out EN for pumps and machinery, medical equipment, aerospace and defense components, and virtually anything that gets hit with moisture or salt on a regular basis. Although mid-phosphorus (5-9%) EN offers greater hardness, high-phosphorus EN is usually the choice when corrosion is of greater concern,

EN works well, but only when the process is properly controlled. The chemistry must be carefully balanced, the temperature reliably managed, and if the parts aren’t cleaned properly beforehand, that’s basically asking for trouble. High-strength steels often need a heat treatment afterward to drive off hydrogen that can embrittle a part but that’s just one more element in creating a high-quality finish.

Why Engineers Keep Coming Back

EN is often referred to as an “engineered finish” because it is so consistent. It helps maintain close tolerances, handles corrosive environments, and it looks great. That’s probably why so many engineers keep coming back to it.